I’ve been making progress on my CNC project. The progress is the main reason I haven’t really been posting much.

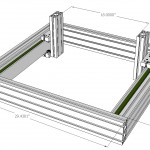

I decided to build an ‘ugly’ maching in order to get a really good one going. In this vein I am going to build a variation of a Joe2006 machine. Then with that one built, learn the basics, and either build out a real Joe2006 or build up a 4’x2.5′ version of a Joe4x4. Anyway, that is the plan.

So what have I got so far? A gantry, and a HobbyCNC Pro kit. I have the HCNCPro kit built and am configuring it. So far so good, and I should have stepper motors spinning soon. I got the kit on sale for $300 all up. This brings the total cost up to about $380.

I still have to get some expensive stuff. These items include Acme lead screws (McMaster Carr p/n-98940A627 x2, 92940A623 x1), and then a lead nut kit (DumpsterCNC the Joe CNC Router deluxe kit), plus software. I’m looking at the Cut 2-d from Ventric, this will get me the G-Code and some other features. Then I can run the EMC2 open source software to acutally control the machine and run the G-Code.

So I should be able to get a working machine for about $900.